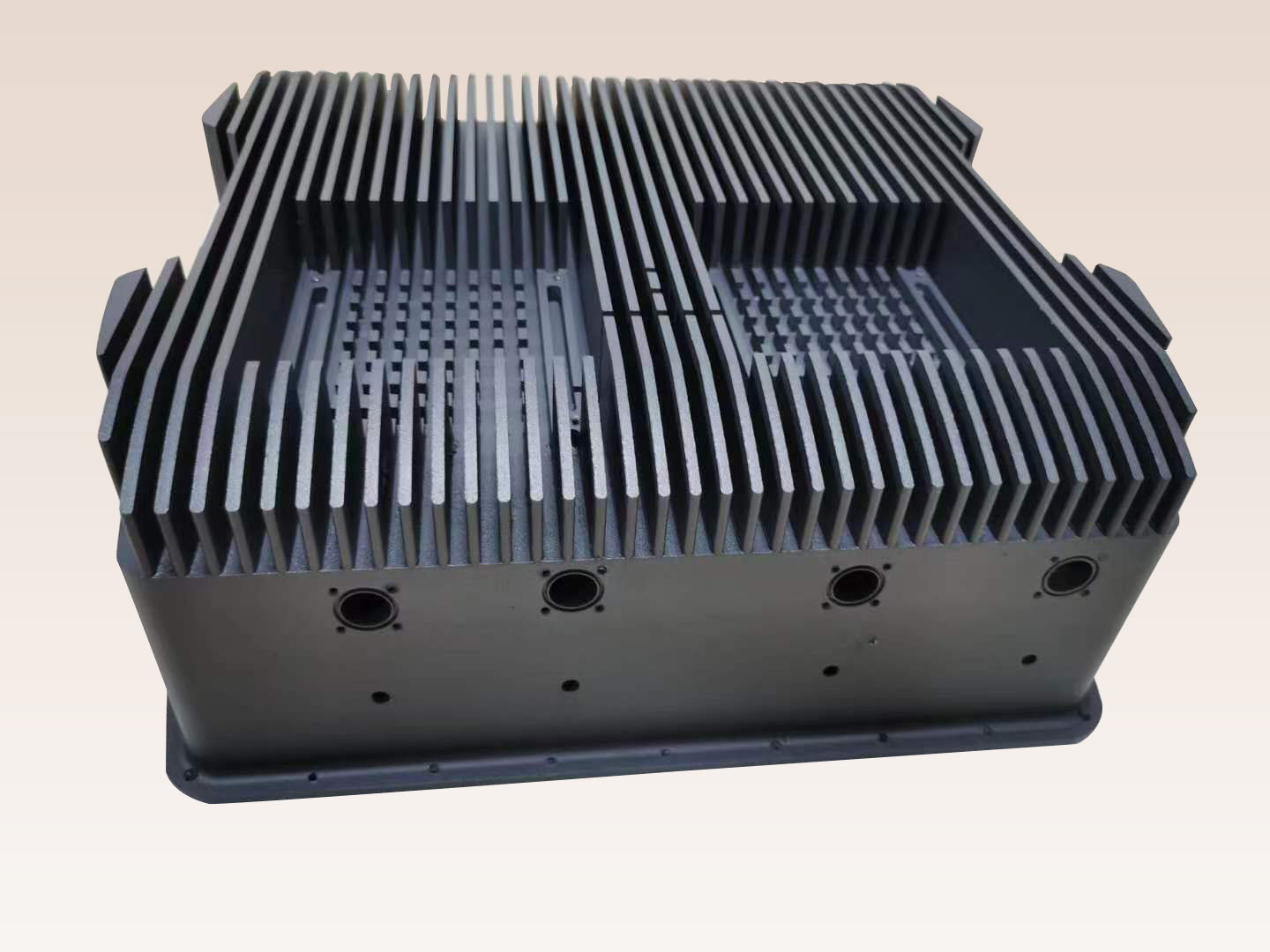

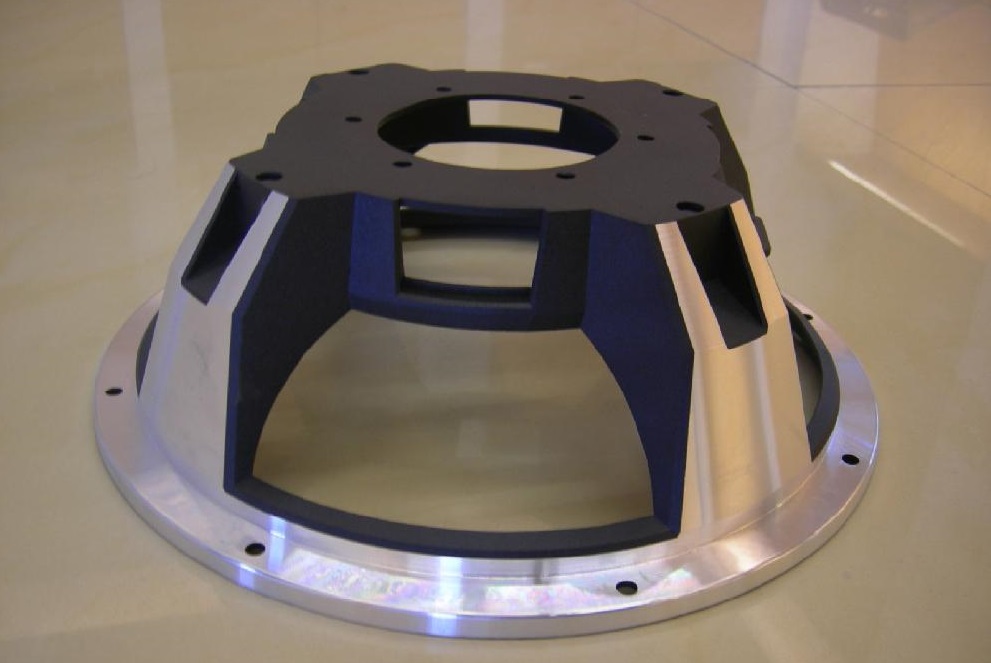

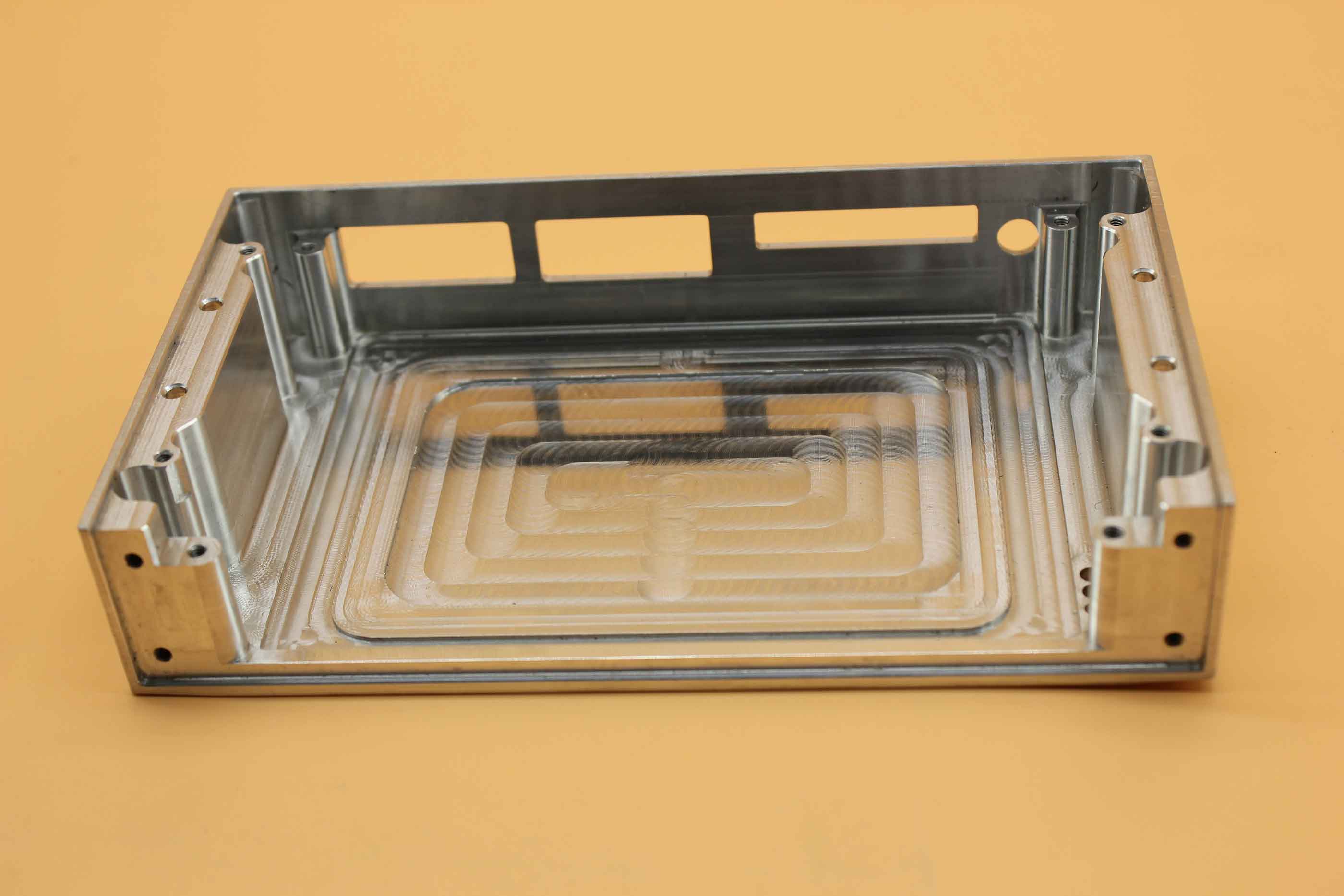

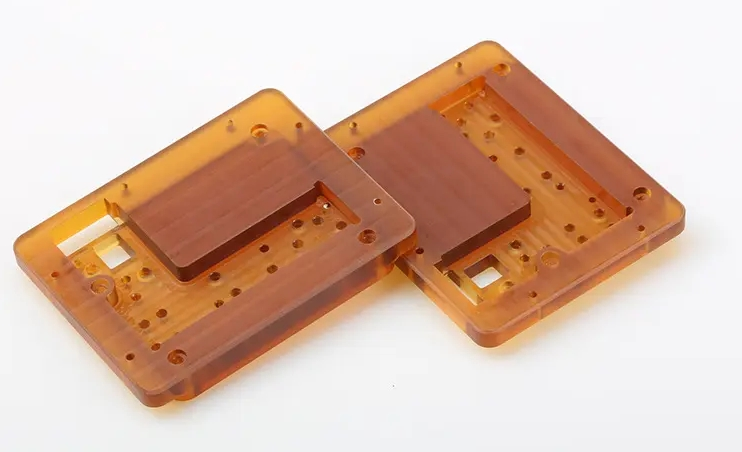

We have a variety of precision machining equipment, there are: computer gongs, CNC lathes, engraving machine, CNC Machining Center, Precision Grinder, precision cylindrical grinder, wire cutting, spark machine and other precision machining equipment. Main processing all kinds of high-speed steel, alloy steel, stainless steel, aluminum alloy, titanium alloy, magnesium alloy, special plastic PEI, PPS, Peek and other high-precision parts. Main application: hardware tools, precision machinery parts, precision instrument parts, die parts, aviation, automobile, medical, energy-related precision parts.

Computer gong, also known as CNC (Computer Numerical Control) CNC milling machine. In English, it means a milling machine controlled by an electronic meter digital signal.

1. The parts have strong adaptability and flexibility, and can process parts with particularly complex contours or difficult to control dimensions, such as mold parts, shell parts, etc.;

2. It can process parts that cannot be processed by ordinary machine tools or are difficult to process, such as complex curved parts described by mathematical models and three-dimensional space surface parts;

3. Parts that need to be processed in multiple processes after one clamping and positioning can be processed;

4. High processing precision, stable and reliable processing quality, the pulse equivalent of the digital controlle is generally 0.001mm, and the high-precision numerical control system can reach 0.1μm. In addition, the numerical control processing also avoids the operator's operation errors;

5. The production automation is high, which can reduce the labor intensity of the operator. Conducive to production management automation;

6. The production efficiency is high. The computer gong uses special process equipment such as special fixtures. When replacing the workpiece, it only needs to call the processing program, clamping tool and adjusting tool data stored in the numerical control device, thus greatly shortening the production cycle. Secondly, the computer gong has the functions of milling machine, boring machine and drilling machine, which makes the process highly concentrated and greatly improves the production efficiency. In addition, the spindle speed and feed speed of the computer gong are Continuously VariableTransmission, so it is beneficial to choose the best cutting amount.

CNC lathe, also known as CNC Lathe is one of the widely used CNC machine tools. It is mainly used for the machining of inner and outer cylindrical surfaces of shaft parts or disk parts, inner and outer conical surfaces of arbitrary cone angles, complex rotary inner and outer curved surfaces, cylindrical and conical threads, etc. , and can cut grooves, drilling, reaming, reaming and boring and so on.

CNC machine tool is in accordance with the pre-prepared processing program, automatically to be processed parts processing. We put the parts of the machining process, process parameters, tool trajectories, displacement, cutting parameters and auxiliary functions, according to the instruction code and program format of the CNC machine tool, write the processing program sheet, record the contents of the program sheet on the control medium, and then input it into the CNC device of the CNC machine tool, so as to command the machine tool processing parts.

In the hardware processing, the rotary parts that can be clamped on the ordinary lathe can be processed on the numerical control lathe. However, CNC lathes are characterized by high machining accuracy, linear and circular interpolation, and automatic speed change in metal machining, and their processing range is much wider than that of ordinary lathes.

CNC lathe can not only turn any straight lead, cone and end-face thread, but also turn variable lead and variable lead between the smooth transition of the thread. CNC lathe thread when the spindle rotation does not have to be like ordinary lathe as alternating, it can be a knife and a knife without stopping the cycle, until the completion, so the efficiency of CNC lathe thread is very high.

Wire Electrical Discharge Machining (WEDM) is an Electrical Machining process in which the instantaneous high temperature of an Electrical Discharge (EDM) causes local metals to melt, oxidize and corrode Electrical Discharge Machining. Wire cutting can cut metal materials such as: high strength, high toughness, high hardness, high brittleness, magnetic materials, as well as the precision of small and complex shape parts, processing the highest accuracy can reach 0.001 mm, it is widely used in die parts processing, high precision machine, tool, aviation, automobile, military industry and other parts processing.

Electrical Discharge Machining (EDM) is a type of Machining equipment used primarily for Electrical Discharge Machining. Widely used in a variety of metal mold, mechanical equipment manufacturing. It is a special machining method, also called electrical discharge machining or electrical etching machining, which is used to etch conductive materials by means of the electric erosion produced by pulse discharge between two poles immersed in working fluid. It is mainly used for machining the mould and parts with complicated shape, such as holes and cavities, and for machining all kinds of conductive materials, such as cemented carbide and quenched steel, etc. Processing deep fine hole, special-shaped hole, deep groove, narrow slot and cutting slice, etc. .

Processing various blade tools, samples, and thread ring gauge and other tools.