CNC bending machine is equipped with the mold (general or special mold) will be cold under the metal plate bending into a variety of geometric cross-section shape of the workpiece. It is a sheet forming machine designed for cold-rolled sheet metal processing. It is widely used in sheet bending processing of automobile, aircraft, light industry, shipbuilding, container, elevator, railway vehicle and other industries.

CNC bending machine is usually used special CNC system for bending machine, the axis of bending machine has been developed from single axis to 12 axis, it can automatically control the running depth of the slide, adjust the left and right slope of the slide, adjust the front and back of the rear stopper, adjust the pressure tonnage, adjust the working speed of the slide and so on. The Bender can conveniently realize the action of slider down, point-moving, continuous, pressure-keeping, return and stop in the middle, and complete the bending of multi-bends at the same angle or different angle at one feeding.

The repeated precision of the slider is ± 0.0004 inches. The precise angle of forming must adopt such precision and good die. The repeatability of the manual press brake slider is ±0.002 inches, and the deviation is ± 2 ~ 3 ° when the suitable die is used. In addition, the CNC Bender is ready for rapid die mounting, which is an unquestionable reason to consider when you need to bend many small parts.

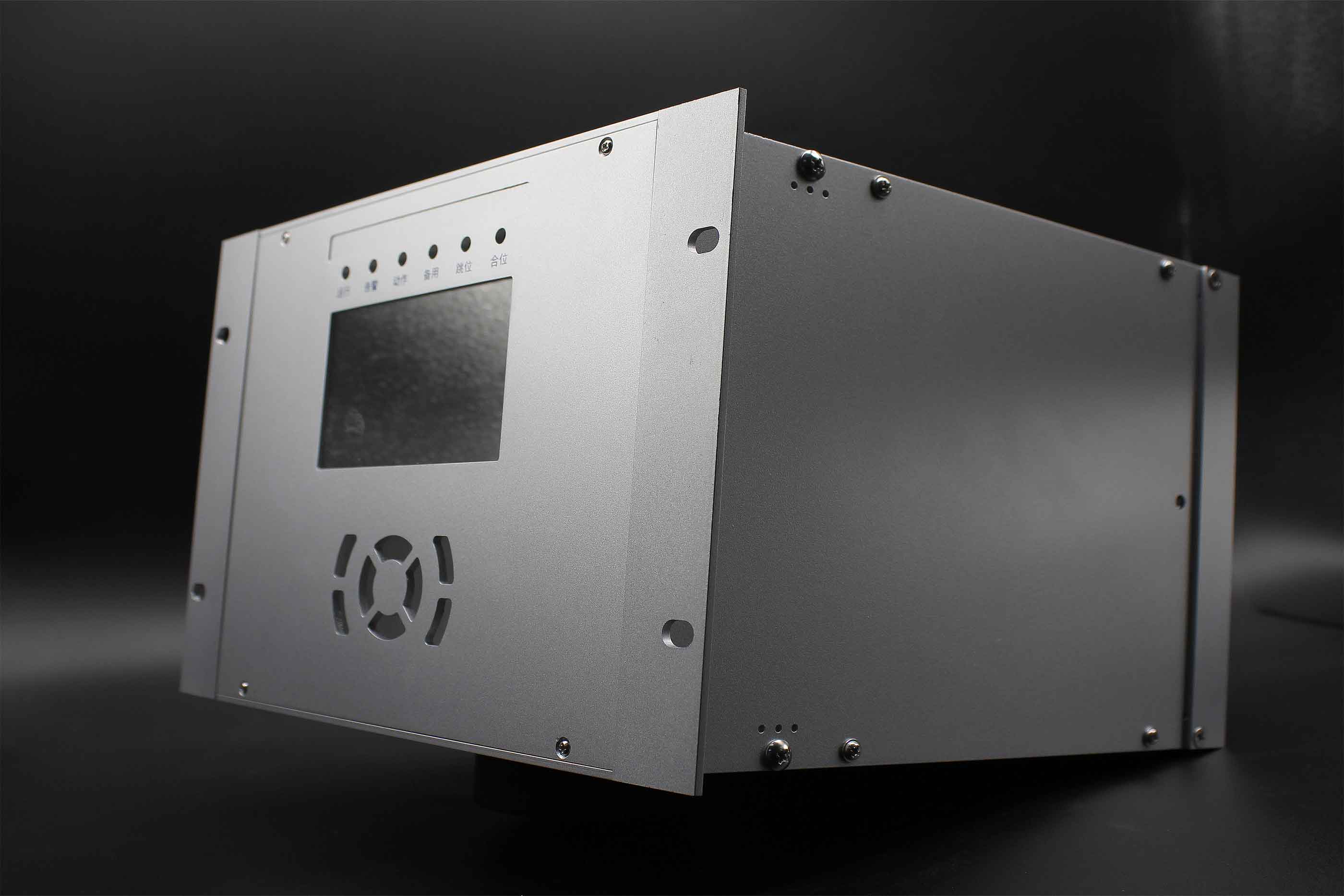

Industrial chassisMaterial: AL5754 process: laser + CNC bending + computer gongs + sandblasted anode + laser logo + assembly

Industrial chassisMaterial: AL5754 process: laser + CNC bending + computer gongs + sandblasted anode + laser logo + assembly Industrial chassisMaterial: Q235 process: laser + CNC bending + lathe + computer gong + welding + powder spraying + screen printing Logo + assembly

Industrial chassisMaterial: Q235 process: laser + CNC bending + lathe + computer gong + welding + powder spraying + screen printing Logo + assembly Industrial equipment accessoriesMaterial: SUS316 process: laser + wire drawing

Industrial equipment accessoriesMaterial: SUS316 process: laser + wire drawing Industrial equipment accessoriesMaterial: Q345 process: laser + manipulator welding + lathe + galvanized

Industrial equipment accessoriesMaterial: Q345 process: laser + manipulator welding + lathe + galvanized